Choosing The Right Finish For Your Label

Which products typically catch your eye?

According to research, it’s those with exceptionally stand-out packaging.

Did you know the finish used on your label plays a huge part in whether your packaging blends in or stands out from the competition?

From vibrant and reflective to soft and smooth, there are many label finishes that can set a product apart.

Let’s walk through the two most effective label finishes: glossy and matte/satin

Glossy

Typically, glossy finishes are created by a gloss liquid-applied varnish, forming a protective layer once cured and dried.

Glossy labels are naturally eye-catching and vibrant.

Due to their reflective nature, they give labels a sleek and shiny appearance. By reflecting light from all angles on the label surface, glossy labels also enhance colors and highlight details.

Since this crisp and polished look creates bright colors and sharp contrast, it’s the perfect option for new and innovative products as they’ll shine (literally!) in a fresh and exciting way.

Glossy labels are also fantastic when paired with designs that have complex color schemes or high-contrast, detailed graphics. Their reflective nature highlights features in a rich way, without dulling or muting details.

This finish is also perfect for low-light environments, or in places where the product needs to stand out…for example, Ghost Energy uses a stunning glossy shrink sleeve label for their energy drinks. The neon colors are incredibly vivid, and the cans glint in the light, drawing consumers’ eyes away from other competitors!

Satin and Matte

Satin and matte are two finishes that are similar in appearance, however, a satin finish typically refers to UV varnishes while matte usually refers to laminates.

To make matte labels, matte finish is laid on top of the raw label material after the label ink has been printed.

In contrast to glossy labels, matte labels produce a subtler effect. This finish has a satiny appearance that mutes the look of colors and prints. It also creates smooth labels that feel soft and are satisfying to touch.

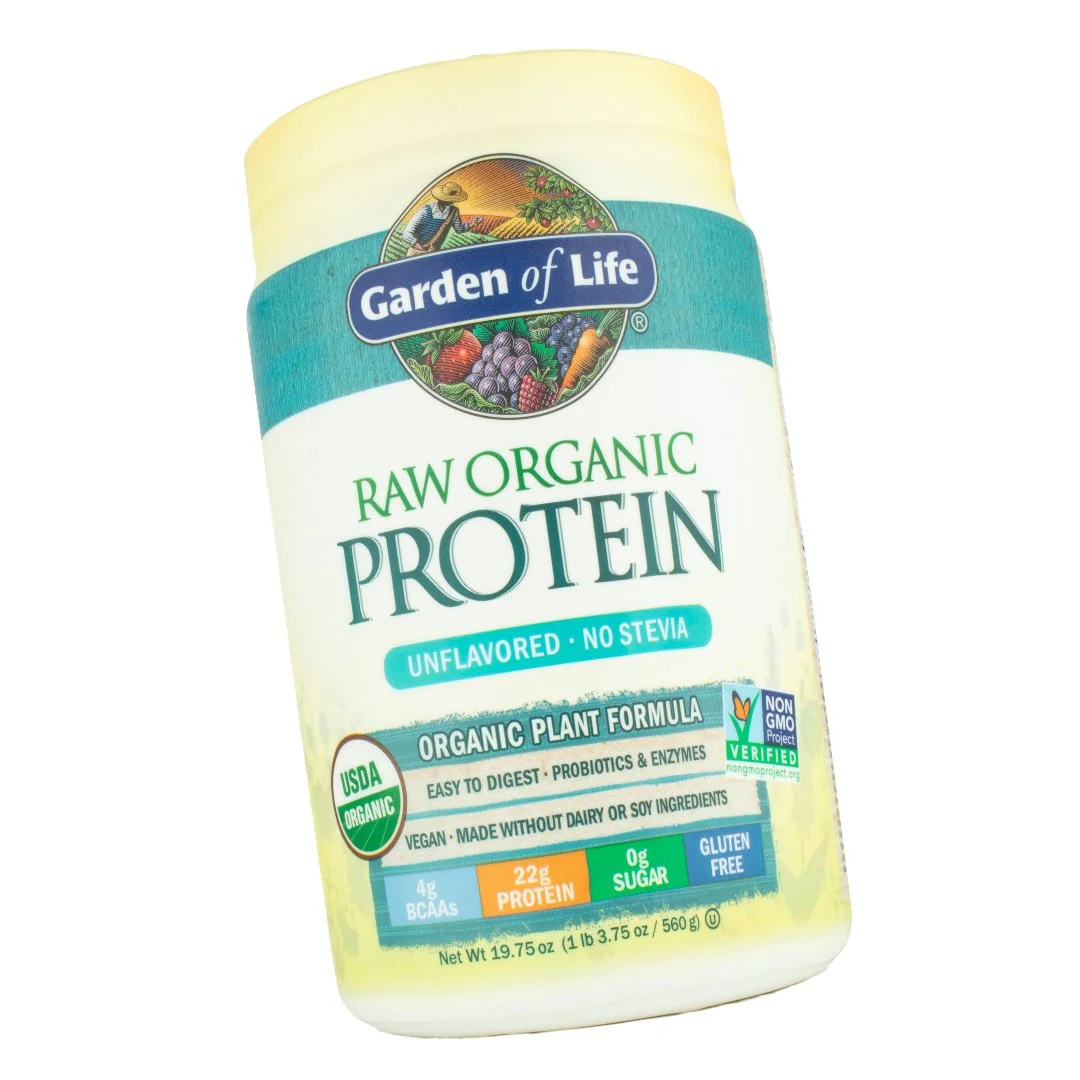

These labels are ideal for handcrafted, organic, and natural-looking products.

Matte is the perfect finish for emphasizing natural, high-quality ingredients in any kind of product, from food to personal care.

Matte labels give such products a vintage appeal and a more authentic look, with a timeless and high-quality allure.

Matte labels are also fantastic for luxury products.

These labels are often used for upscale food and beverage products, beauty products, and alcohol products. Matte is elegant and sophisticated in its look and feel.

Matte and satin coatings also allow for other packaging elements to stand out and capture customer attention, whether it’s a unique label design or innovative container shape.

For instance, this finish works well with a range of interesting textures, such as unique hand-written designs. Without a glare from gloss, these details show through more clearly.

This nonreflective quality also makes matte labels ideal for shipping and address labels, QR codes, and scanners for barcodes.

Other Factors To Consider

It’s often said that no man is an island – and no label is an island, either!

The material surface of your product is an important factor in deciding what finish to use for your label.

Labels can be applied to wood, metal, glass, and plastic, and the application can vary depending on what finish is used. Different finishes are more flattering on different surfaces, so it’s important that the label matches the application surface.

Matte labels are great to enhance the satiny look of frosted containers, while glossy labels can add extra shine to glass bottles and jars.

Selecting a Label Finish For Your Product

With so many benefits to both options, it’s up to you and your team to decide what finish is the best fit to make your unique product stand out, but Tango Packaging is here to help.

From advice in making the initial decision, to complimentary samples of each option, and even applying finishes in-house as we produce your labels, our Tango team is ready and available to help you produce your dream product.

Step 1. Schedule a packaging consultation with one of our packaging experts. We’re happy to help you find what works best for your specific product. Tango can provide both glossy and matte finishes, as well as UV inhibitors.

Step 2. We’ll send you complimentary samples.

Step 3. We’ll provide you with a quote.

Schedule your complimentary consultation by filling out our contact form, emailing us at info@tangopackaging.com, or calling (844) 33-TANGO [82646].