Folding Cartons 101

The trusted folding carton.

Invented back in the 1880s, the folding carton is remarkably still used as an active packaging solution today.

But what exactly are folding cartons, how do they work, what products are they used for, and what advantages can they offer?

In this blog we’ll explore all things folding cartons, and see why so many brands have utilized these helpful packaging solutions for the last 100+ years.

What is a folding carton?

Folding cartons are boxes or box sleeves, typically made from paperboard. These boxes are produced by machines that cut, glue, crease, and score the box material to create the right size and shape for the boxes.

Folding cartons are produced and shipped flat, and then unfolded and assembled at the manufacturing facility.

Paperboard, the material most folding cartons are made of, is a type of fiberboard made to stand against creasing, allowing it to fold and bend.

The smoothed, coated board also creates a better surface for printing.

Laminates or foils can add to the folding carton’s aesthetic and/or functional use.

There are a variety of types of paperboard used for folding cartons, such as Solid Bleached Sulfate, Coated Recycled Board, Clay Coated News Back, and many other options.

Another choice is corrugated cardboard, which is more rigid and stiff than other options.

The designs for folding cartons can be printed with offset lithography or with digital printing. Lithography is commonly used for longer runs. This method can apply inks, coatings, and foil in one pass, rather than through multiple processes or machines. Digital printing is perfect for folding carton customization and is often used for shorter runs or special projects.

Various Folding Carton Solutions & Their Uses

Different folding cartons are typically used for different products.

Auto-lock bottom boxes, or crash bottom boxes, have a tuck flap on top and bottom flaps that lock into place during assembly.

These boxes are well suited for heavy objects, and are often used to package candles, wine bottles and craft beers, automotive products, grocery items, and more.

Straight tuck boxes feature top and bottom panels that close on the same side of the box. These panels fold front to back in the same direction, with slits to keep the ends in place.

These boxes are easy to store and assemble, and are perfect for light to medium products such as cosmetics, essential oils, and other small personal care items.

Reverse tuck boxes are very similar to straight tuck boxes, but simply have different end closures: they’re on opposite sides of the box, instead of the same side, which makes the panels fold in opposite directions.

These boxes can hold the same products as their straight tuck counterparts.

Snap bottom or lock bottom boxes feature bottom flaps that push into each other to lock. Similar to auto-lock bottom boxes, this option is perfect for heavier products, such as bottled beer and wine, books, and heavy electronics.

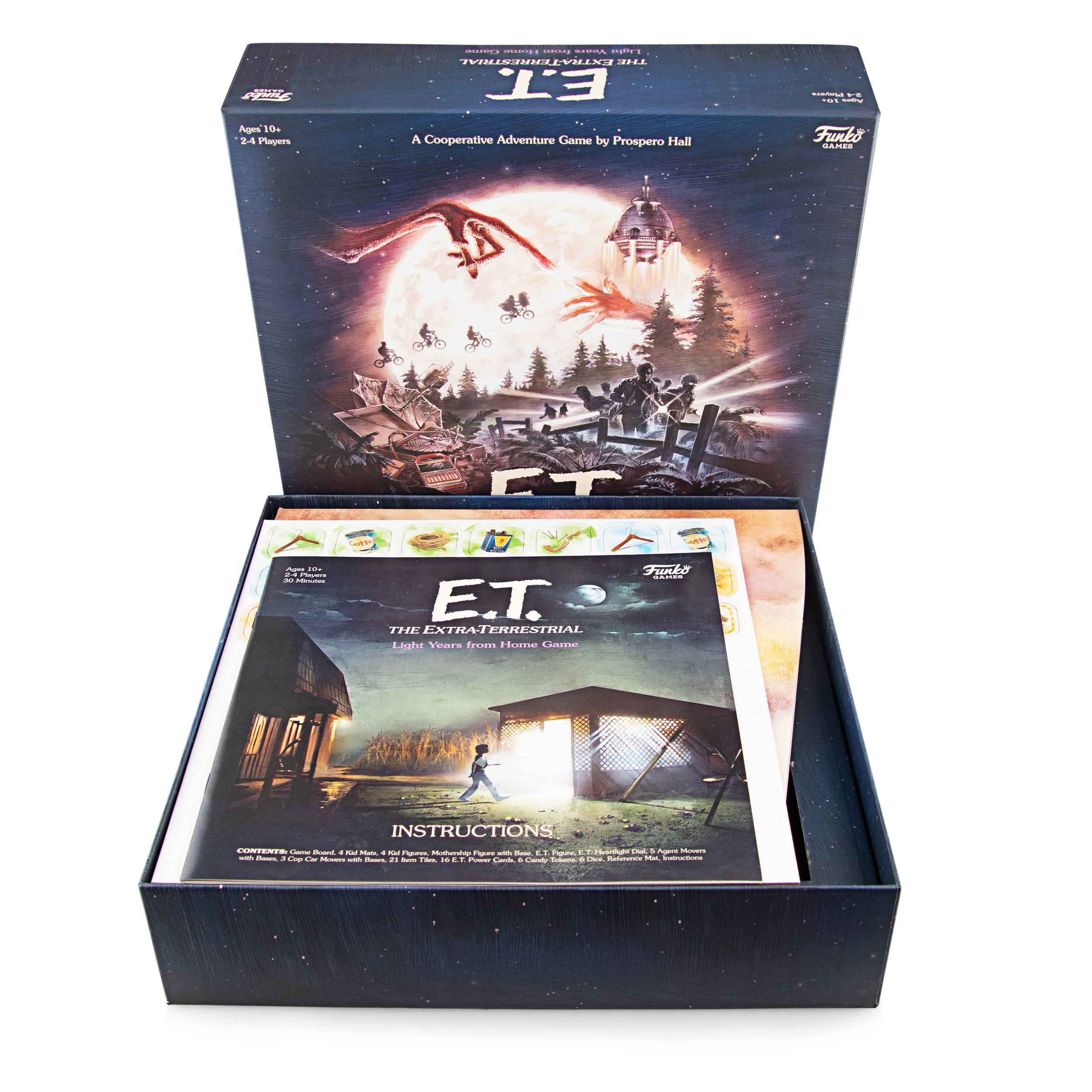

Telescopic boxes have a separate top and bottom that fit over each other. These boxes can have multiple walls to make them more long-lasting, and there are various shapes and sizes used.

This style is perfect for irregular shaped products, or higher-end products like jewelry, clothing, confections, and more.

What are the advantages of folding cartons?

Durable and resistant - Folding cartons will protect your product. Paperboard comes in various weights and styles, allowing you to adjust the rigidity of the box to your product’s unique needs! Folding cartons are inherently more structurally strong and rigid than many other types of packaging.

Efficiency - Since they are produced and shipped flat, folding cartons save space during transportation, increasing production capabilities and reducing costs.

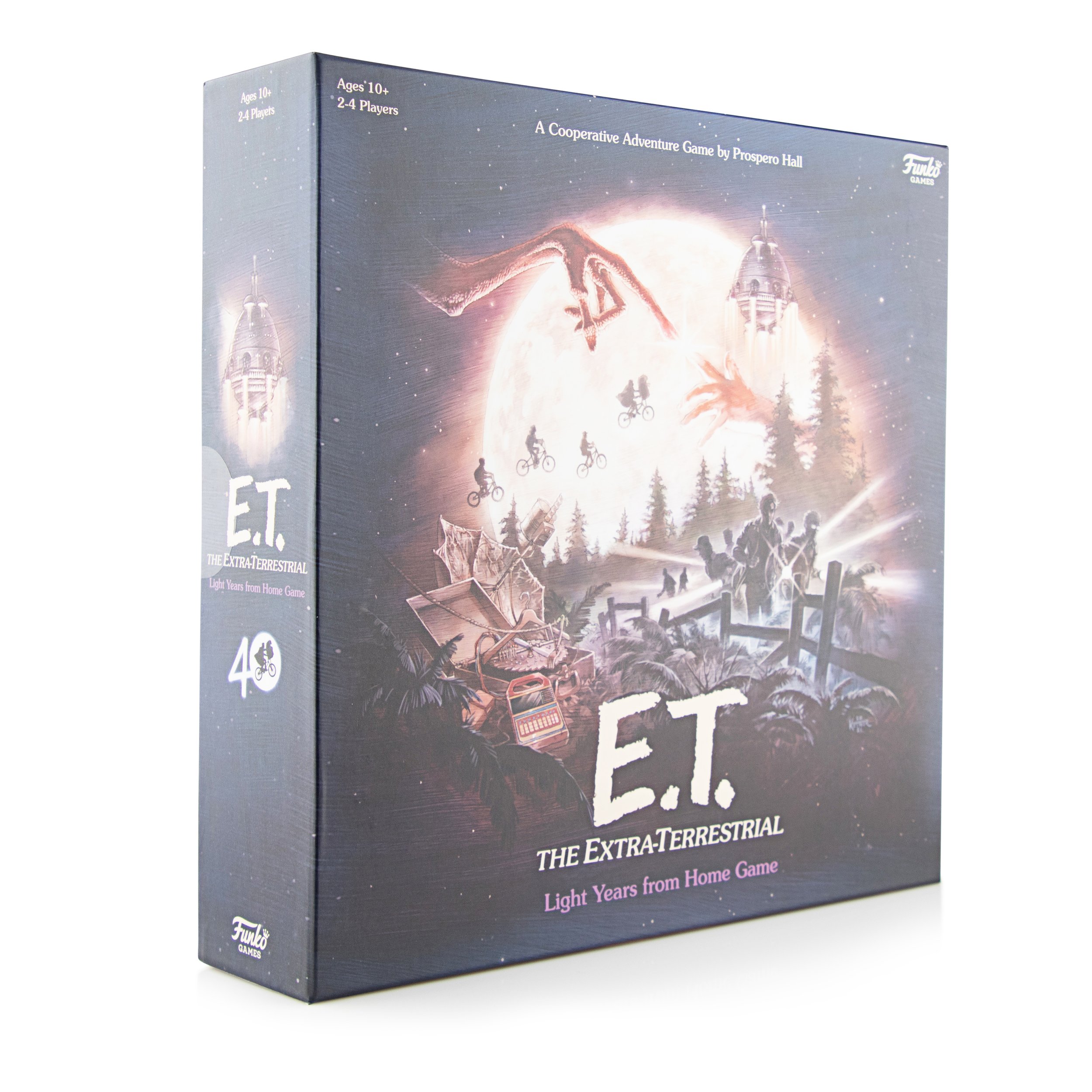

Highly customizable - Folding cartons come in a wide variety of shapes and sizes to fit your needs. You can even create boxes with custom dimensions, unique to your product. Custom enhancements include embossing/debossing, foil stamping, textures, and unique lettering and graphics. There are many different ways to make your specific folding cartons stand out!

Convenient features - Folding cartons have a variety of functional and aesthetic features that make consumer use easier. Examples include handles for carrying folding cartons, telescoping boxes which are perfect for shipping, and the option to print on the inside and outside of boxes. This printing choice adds a premium feel to folding cartons, and can often be seen in personal care, cosmetics, or high-end clothing boxes.

Sustainable - Paperboard is made from wood pulp, which is a renewable source. Not only is paperboard made from recycled materials, but it can also be easily recycled again after use.

Are folding cartons a good fit for you?

If you think folding cartons might be the right solution for your product, we’d love to help walk you through the process and fit your specific product with unique solutions.

Step 1. Schedule a packaging consultation with one of our packaging experts. We’re happy to discuss your product in light of our solutions and services. [Or whatever fits best.]

Step 2. We’ll send you complimentary samples to test.

Step 3. We’ll provide you with a quote.

Schedule your complimentary consultation by filling out our contact form, emailing us at info@tangopackaging.com, or calling (844) 33-TANGO [82646].